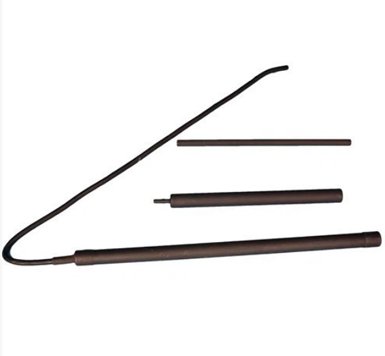

MMO Coated Titanium Anodes

Product name: MMO Tubular Anode

Substrate: Gr1 Titanium

Coating: according to your application

Certificate: ISO9001 Shape: wire, tube, plate, mesh, ribbon

Size: Customization

Free sample available

Delivery time: 20 days

Description

Product Description:

MMO tubular anodes are manufactured by high tensile strength pure titanium tubular substrates coated with noble metal oxides. Mixed metal oxide consumption rates are low in milligrams per amp-year. At the same time, the titanium substrate’s dimensions remain unchanged over the anode’s life, providing consistently low resistance. Whether operating in soil, freshwater, or seawater, mixed metal oxide coatings exhibit high chemical stability, even in low pH environments. Unlike other impressed current anodes, MMO coatings are not affected by chlorine generation. MMO coated titanium anodes provide the longest life and highest current output of all ICCP anodes, and mixed metal oxide coated titanium anodes can operate efficiently in all types of environments.

Different requirements of service life and output current can be designed and produced by adjusting the coating ratio. The coating type, thickness, and anode specifications of MMO titanium anode can be customized. HOWAH team provides you with the most professional custom anodes. Let us know your application environment and we will recommend the most suitable coating.

HappySoul MMO anodes are ASTM B338 Grade 1 or 2 coated with iridium-tantalum-titanium (IrO2/Ta2O5) coating and are widely used in the field of cathodic protection.

Specifications:

| Chemical Composition | |||

| Substrate | Catalyst | ||

| ASTM B 338 Gr 1 Titanium | Mixed Metal Oxide | ||

| Anode Dimension &Properties | |||

| Diameter(mm) | Length(mm) | Current Rating*(A) | Expected life(Y) |

| 16 | 500 | 2.5 | 20~40 |

| 16 | 1000 | 5.0 | 20~40 |

| 19 | 1000 | 6.0 | 20~40 |

| 25 | 500 | 4.0 | 20~40 |

| 25 | 1000 | 8.0 | 20~40 |

| 25 | 1500 | 12.0 | 20~40 |

| 32 | 1200 | 12.0 | 20~40 |

*Anode life can be extended up to longer operating life by increasing the thickness of the MMO coating.

Coating Types:

| Type | Coating Element | Application |

| 1 | IrO2-RuO2- TiO2-X | Suitable for use in seawater where Cl2 is the principal anode product. |

| 2 | IrO2-TaO5-X | Suitable for use in soil, backfill, fresh water, and seawater where O2, Cl2, or a combination of both are discharged at the anode. |

| 3 | Pt/Ti,Nb,Ta | Suitable for use in seawater |

Current output in the different application environments:

| Electrolyte | Maximum Current Density | Anode Life |

| Carbonaceous Backfill | 50 A/m2 | 20 years |

| Calcined Petroleum Coke | 100 A/m2 | 20 years |

| Fresh Water | 100 A/m2 | 20 years |

| Brackish Water | 300 A/m2 | 20 years |

| Sea Water | 600 A/m2 | 20 years |

MMO Tubular anodes can be supplied with all required extras:

• Cable attachment with specific cable length;

• Canister with carbonaceous backfill;

• Heat shrink caps;

• Ropes or suspension assembly;

• Centralizers;

• Client-specific requirement.

RFQ:

Q1. What is your internal inspection procedure, how do you inspect your products?

A: Regarding the internal inspection procedures, There are 6 steps: Material, mechanical processing, surface treatment, coating, cable connection, and packing.

Every step has a responsible leader, the inspector checks carefully every step with professional records, operation files, check subjects, and performing programs. Once problems are checked out, steps will be taken to make up.

Q2. Do you have any certificates for your tests from any third party (like SGS, etc)?

A: Yes, we do have some test certificates from famous third parties, like St Louis testing laboratory and china classification society, etc.

Q3. How can I get the quotation?

A: Please tell us your application environment and the anode specifications.