MMO Linear Anode

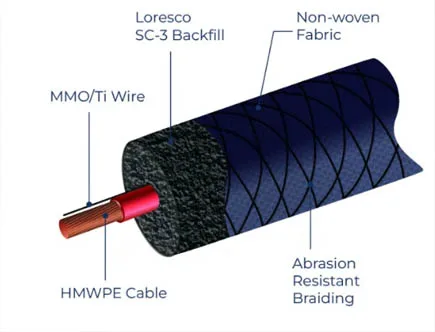

MMO linear anodes, also known as flexible anodes, are an ideal product for use when a low-current, evenly distributed cathodic protection system is needed. The core of the anode is composed of high-grade, titanium wire with a Ir–Ta mixed metal oxide catalyst coating. The titanium wire is prepackaged in a porous, non-woven fabric “sock” that contains high conductivity calcined petroleum coke breeze —— enhancing the anodes abrasion and damage resistance.

The power cable attached is #6 AWG stranded copper with either high molecular weight polyethylene (HMWPE) insulation or a dual insulation of Kynar/HMWPE. This cable has the capacity to maintain the required current over considerable distance without incurring substantial longitudinal voltage drop.

The MMO linear anode has the advantage of easy installation and handling as well being cost efficient. Typical uses for this anode include the impressed current cathodic protection of in-plant piping, buried oil (gas) pipelines, petrochemical container, tank bottoms and other underground structures.

Description

Key Features

Quality Substrate Material

Oue linear anode is comprised of Gr1 or Gr2 titanium wire (ASTM B348) with IrO2/Ta2O5 based MMO catalyst coating. Unique sintering coating technology allows for long product life.

Evenly Backfill Filling

High performance calcined petroleum coke breeze is tightly pre-packaged and evenly distributed all around the anode, serving as the active matrix in which the electrochemical reactions take place.

Protective Braid Fabric Jacket

MMO linear anode is prepackaged within porous, woven acid-resistant synthetic sleeve. This tough sleeve is sewn together using a poly two or four-thread double interlocking stitch, which prevents the seam from separating during installation, or when stored in high temperature conditions.

Reel Packing for Easy Transportation

The sock diameter is approximately 1.5 inches and is installed directly, from the factory provided reel, into the trench. Wooden or steel reels are supplied as required.

Reliable Connection

The MMO titanium wire is connected to the power cable in parallel via a heavy-duty crimp to ensure low resistance. The connection joint is then sealed in a splice kit with epoxy resin to prevent water intrusion.

Main Technical Parameters

| Substrate | Titanium |

|---|---|

| Coating | Iridium Oxide (IrO2), Tantalum Oxide (Ta2O5) |

| backfill | Calcium Petroleum Coke |

| Shape | Wire |

| Application | Pipelines, Storage Tank |

| environment | Soil |

| Design Life | 25 years |