Considering the appearance, cost and safety, many owners will consider using underground storage tanks. To minimize the rusting of steel tanks and connected piping which can cause a release of a regulated substance, it is necessary to protect steel vessels from moisture and chemicals in the soil.

Protecting underground tanks from corrosion is easily achieved by the use of two commonly applied protection methods:

1. External coating

2. Cathodic protection

These two methods are complementary and should be used in conjunction with the other.

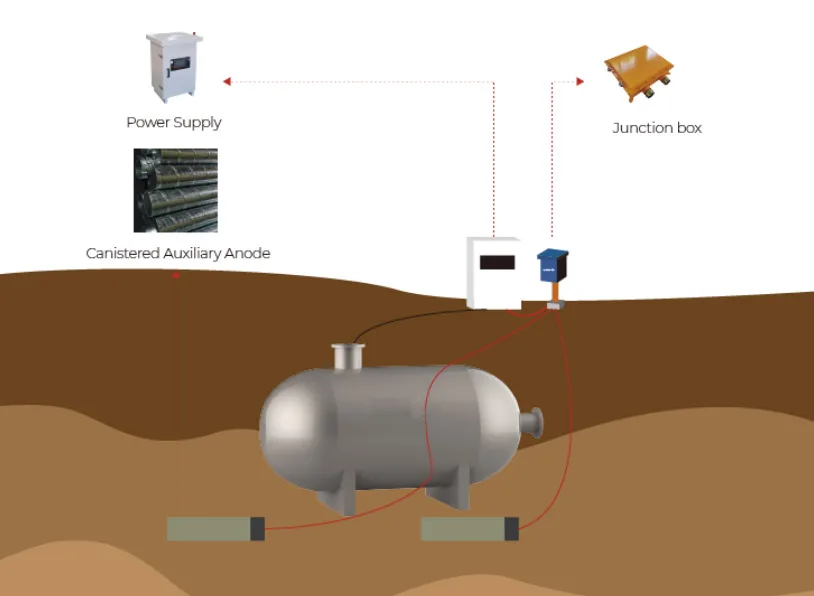

Cathodic protection prevents corrosion at those defects by applying DC current from an external source, forcing the tank to become cathode. Application of sufficient DC current to the tank will prevent any corrosion from occurring. The two general types of cathodic protection systems are sacrificial and impressed current. Sacrificial systems are used when the amount of current required for the protection is small, such as in underground propane tanks. Impressed current systems are more commonly used for large structures.

With the use of cathodic protection systems, the costs associated with environmental clean-up caused by the discharge of underground storage tank systems can be effectively eliminated, and the service life of the storage tanks can be well extended.

Recommend Products