Subsea pipelines are designed with an external coating as the primary system for corrosion control. Still, a cathodic protection system is normally provided as a back-up to account for any deficiency in the coating system. Such deficiencies may include holidays during coating application, damage to the coating during transportation and installation of coated linepipe, and mechanical damage or other coating degradation during operation of the pipeline. In defining the required capacity of the CP system, the detailed design of the applicable pipeline coating systems and the provisions for quality control during their application are consequently the primary factors.

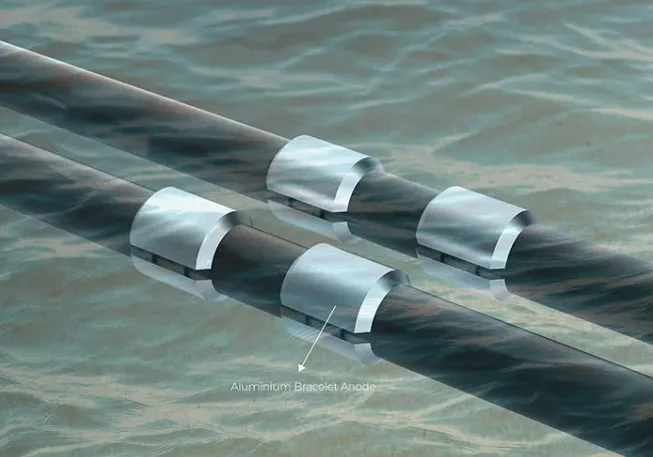

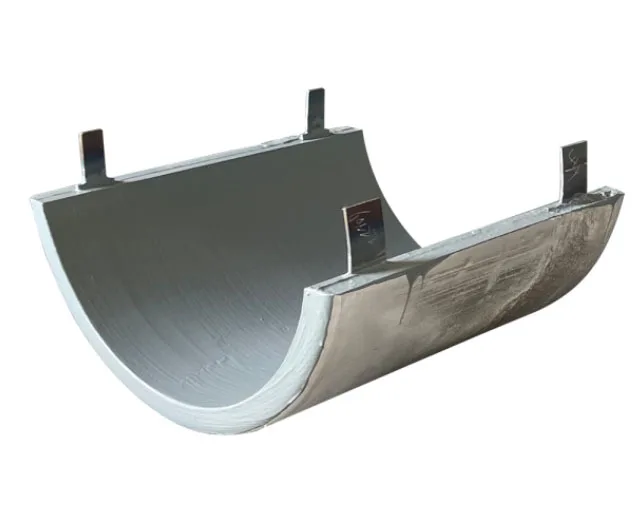

Cathodic protection of pipelines can be achieved using galvanic anodes, or impressed current from one or more rectifiers. For subsea pipelines, galvanic anode systems are most commonly applied. Such systems have traditionally been designed as self-supporting systems with all anodes installed directly on the pipeline itself using bracelet type anodes clamped around the pipeline and individually electrically connected to the pipe.

Recommended Products