Internal corrosion of metallic above ground storage tanks that contain or may contain conductive electrolytes is an issue that cannot be overlooked. Numerous factors can cause internal corrosion including but not limited to types of materials present, electrolyte chemistry, temperature, presence of coatings, and process flow characteristics.

The methods and procedures used to control corrosion should be governed by the rate of corrosion and the cost of maintaining the tank, including the water quality and planned useful life of the tank. Although coatings provide first-line protection, but all coatings are subject to damage and deterioration. Therefore, corrosion control by use of coatings alone on the submerged surfaces of a steel water storage tank is not recommended. By pairing protective coatings and cathodic protection, it is possible to extend the life of a typical steel water storage tank’s coating system for immersion service by as much as 20 years.

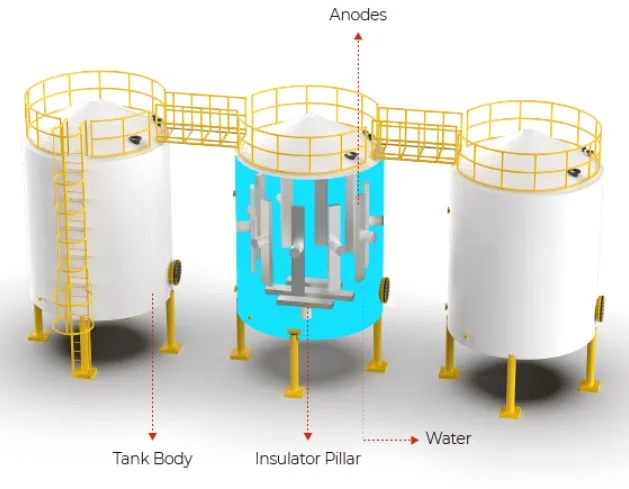

Depending on the efficiency of the coating, the type of cathodic protection system may be either a galvanic anode system or, where more protection current is required, an impressed current system may be needed.

Over the years, our team of technical experts has installed many cathodic protection systems in tanks. We can provide self-produced materials and equipment to complete projects efficiently and quickly. In addition, our technical service team can commission and monitor cathodic protection systems to ensure the system is working properly.

Recommended Products