A major contributor to concrete deterioration is corrosion of embedded metals. In particular, corrosion of reinforcing steel, corrosion of epoxy coated steel, and corrosion of prestressed concrete when unchecked can eventually lead to major rehabilitation costs or structure replacement.

Cathodic protection is a proven solution to make new and existing structures last longer. Concrete repair alone is not a long–term solution when corrosion is the source of the deterioration. After repairing corrosion–induced spalls and delaminations, there will likely still be chloride–contaminated concrete surrounding the rebar in areas adjacent to the chloride–free patch repair. Unfortunately, this situation can lead to the initiation of secondary corrosion sites in areas around the repair.

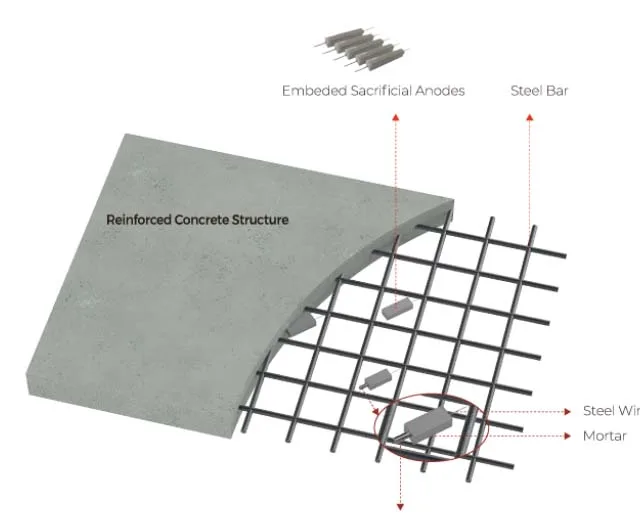

To provide a longer–term solution, there are various cathodic protection methods available. All of the systems are similar in that they deliver a protective current to the reinforcing steel but have different advantages and uses.

1. ICCP systems consist of permanent inert anodes, such as MMO titanium mesh and ribbon, conductive ceramics or conductive coatings and an external DC power source to supply sufficient current is delivered to the steel to overcome the natural concrete corrosion activity.

2. Galvanic protection systems utilize galvanic anodes which are metals with sufficient voltage difference with respect to the corroding steel that protective current will be discharged from the anode though the environment to the corroding structure.

Recommended Products