4 Types Titanium Anode and Its Applications in Various Fields

Introduction: Titanium anodes,a crucial component in numerous industries,because of their exceptional corrosion resistance and durability, and electrochemical properties. In this article, we will explore the different types of titanium anodes,and dig into their diverse applications across various fields.

Types of Titanium Anodes:

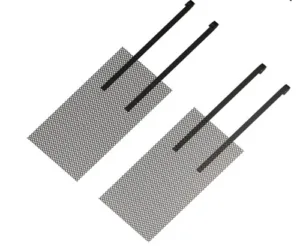

- MMO (Mixed Metal Oxide) Coated Titanium Anodes: MMO-coated titanium anodes are widely used in electrolytic processes due to their high efficiency and stability. The thin, catalytic oxide coating enhances their electrocatalytic activity, making them suitable for applications in water treatment, electroplating, and cathodic protection systems.

2.Platinum-Clad Titanium Anodes: Platinum-clad titanium anodes are renowned for their exceptional chemical resistance and long service life. They find extensive utilization in industries such as chlorine and caustic soda production, electrochemical synthesis, and organic electrolysis.

2.Platinum-Clad Titanium Anodes: Platinum-clad titanium anodes are renowned for their exceptional chemical resistance and long service life. They find extensive utilization in industries such as chlorine and caustic soda production, electrochemical synthesis, and organic electrolysis.

3.Ruthenium Oxide (RuO2) Coated Titanium Anodes: Titanium anodes coated with RuO2 are highly effective in applications involving the generation of chlorine, oxygen, and other oxidizing agents. They are commonly employed in chlor-alkali cells, water disinfection systems, and industrial wastewater treatment processes.

4.Mixed Metal Oxide-Iridium (MMO-Ir) Coated Titanium Anodes: MMO-Ir coated titanium anodes exhibit excellent stability and durability in harsh environments, making them ideal for applications in the electronics industry, electroplating, and metal electrowinning processes.

Applications of Titanium Anodes:

- Water Treatment: Titanium anodes play a vital role in water treatment processes, including electrochlorination, electrolytic ozone generation, and electrocoagulation. Their corrosion resistance are pretty good,their high efficiency make them indispensable for disinfection, desalination, and purification of water in swimming pools, municipal water treatment plants, and industrial settings.

Read More:

Swimming Pool disinfection:

https://happyelectrode.com/applications/swimming-pool-disinfection/Sewage treatment:Sea Water Desalination:

- In Metal Finishing and Electroplating field: titanium anodes offers superior performance In electroplating applications,and They ensure precise metal deposition, even in demanding conditions. Their resistance to chemical attack and stability make them suitable for plating various metals like gold, silver, nickel, and copper.

Read More:

Electroplating:

https://happyelectrode.com/applications/electroplating/Printed Circuit Board Production:

https://happyelectrode.com/applications/printed-circuit-board-production/

- Cathodic Protection: Titanium anodes are extensively used in cathodic protection systems to prevent corrosion of metallic structures such as pipelines, ships, offshore platforms, and underground storage tanks. They provide reliable and long-lasting protection against galvanic corrosion, safeguarding critical infrastructure.

Cathodic Protection For Reinforced Concrete Bridge Piers:

Cathodic Protection For Offshore Wind Turbine Foundations:

https://happyelectrode.com/applications/impressed-current-cathodic-protection-for-offshore-wind-turbine-foundations/ - Electrowinning and Electrosynthesis: Industries involved in electrowinning and electrosynthesis processes, such as copper refining, metal recovery, and electrochemical production of chemicals, rely on titanium anodes. Their durability and resistance to aggressive environments ensure efficient and cost-effective operations.

Conclusion: Titanium anodes, available in various types like MMO-coated, platinum-clad, RuO2-coated, and MMO-Ir coated, offer remarkable advantages in terms of corrosion resistance, durability, and electrochemical performance. Their applications span across diverse industries, including water treatment, metal finishing, cathodic protection, and electrosynthesis. With their outstanding properties, titanium anodes continue to drive innovation and contribute to the advancement of numerous sectors worldwide.