Showing 1–16 of 64 results

-

Titanium Conductor Bar acts as an inert conductor to electrically connect the MMO Ribbon anode and reduce attenuation losses and also connects to the positive cable via rod connectors.The titanium ribbon is connected to the MMO Anode by spot welds applied at the point of crossover.

-

Howah Bare Magnesium Anode

Chemical Composition: M1C (High Potential) AZ63B (Standard or Low Potential)

Specification:17Ibs/7.7kg 17D3 or customized

-

Howah Prepackaged Magnesium Anode

Chemical Composition: M1C (High Potential) AZ63B (Standard or Low Potential)

Bare Anode Specification:17Ibs/7.7kg 17D3 or customized

Backfill: Hydrated Gypsum, Hydrated Gypsum and Sodium Sulphate

-

Product name: 3mm Diameter MMO Wire Anode

Grade: Titanium Grade 1, Titanium Grade 2

Available anode type: Mesh, sheet/plate,bar/ rod/wire, pipe/tube

Available coating type: Ir02-RuO2-Tio2-x /IrO2-TaO5/Pt/Nb/Ta

Standard: ASTM B863

Certification: ISO9001

Delivery time: 20 days

-

Product name: Aluminium anodes for boats

Material: Aluminum alloy

Size: Customization Size

Certificate: ISO9001

Delivery time: 20 days

-

Ships use seawater for several purposes, and one of the primary functions is cooling the engine and parts of the ship while while sailing. However, as the seawater passes through the various pipes and parts to cool the ship’s engine, marine organisms could deposite along their surface.

To protect and purify the surface of ship’s mechanical parts, our electrolytic anti-fouling anodes combo system function as both anti-fouling agent and corrosion inhibitor. The fouling organisms can be inhibited from growing by dosing small quantities of Cu ions into the water with a total anti-fouling effective rate over 95%. And aluminum hydroxide

colloid formed could provide an anti-corrosive film over the sea water piping system – keeping corrosion rate less than 0.03 mm/year.

This anode combo of copper and aluminium anodes provides a simple method of fouling prevention that is fitting marine growth prevention system (MGPS) on board.

-

Feature:

1. High current efficiency

2. Uniform consumption

3. High potential

4. High current capacity

-

Product name: zinc anodes for boats

Chemical Composition: 99.95%Min zinc

Usage: Cathodic protection,ship anti-corrosion

Standard: ASTM

Free sample available

Size: According to customer’s requirement

Certificate: ISO9001 Delivery time: 20 days

-

Howah Casting Magnesium Anodes

Chemical Composition: M1C (High Potential) AZ63B (Standard or Low Potential)

Specification: 9D3 17D3 32D5

-

PRODUCT DESCRIPTIO New Style Sacrificial Aluminum Tank Anode for oil tank water tank basllast in customized size and shape made in China Howah Aluminum Ballast Tank Anode are designed to provide corrosion prevention for such projects as vessels, Ballast Tanks, Seashore facilities, Marines, Ships…

-

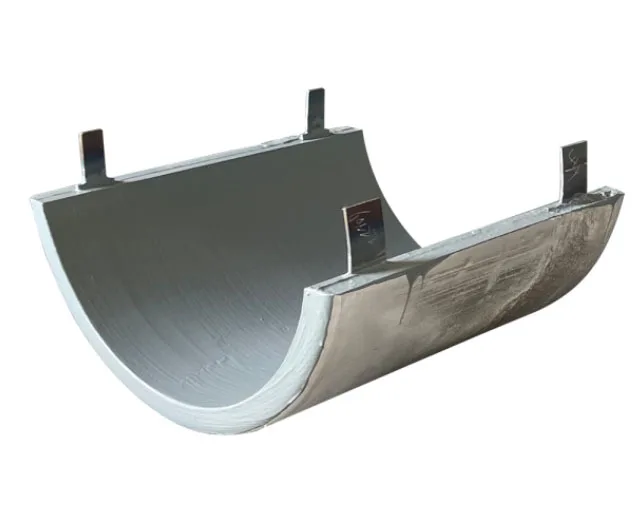

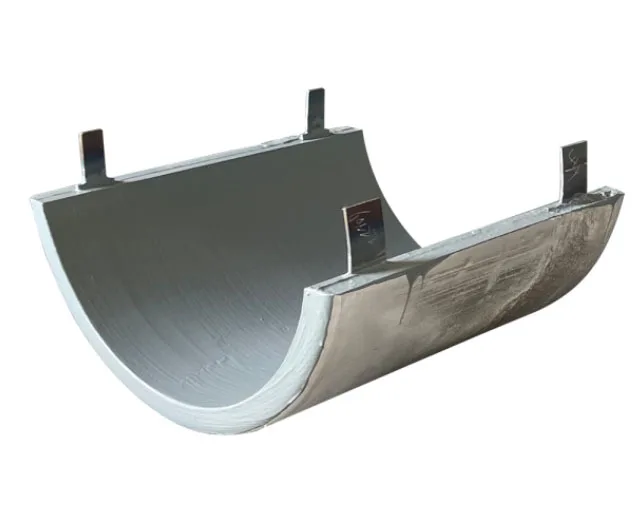

This indium-activated aluminium bracelet anode is specifically designed for the cathodic protection of submarine/offshore pipelines. The half-shell bracelet anode, consisting of two semi-circular sections, is clamped around the pipeline. The electrical continuity between the anode body and the pipe is allowed by a steel continuity bar or by an electrical cable. With square end, our half-shell aluminium bracelet anodes are suitable for flush fitting with concrete coating.

-

This indium-activated aluminium bracelet anode is specifically designed for the cathodic protection of submarine/offshore pipelines. Assembled as two half-shells, the anodes fit the pipe as a bracelet and shall be installed by thermit-welding. With square end, our half-shell aluminium bracelet anodes are suitable for flush fitting with concrete coating.

-

This indium-activated aluminium bracelet anode is specifically designed for the cathodic protection of submarine/offshore pipelines. Assembled as two half-shells, the anodes fit the pipe as a bracelet and shall be installed by thermit-welding. With tapered ends, our half-shell aluminium bracelet anodes are suitable for easy movements over stringer during pipeline laying.

-

Product name: Magnesium anode

Shape: D type / S type / C type

Standard: ASTM B843

Sample: Free

Size: customization available

Certificate: ISO9001

-

High silicon cast iron anodes are the most common anodes used in impressed current systems and in soil buried facilities. The presence of silicon and high chromium in the high silicon cast iron anodes increases the corrosion resistance and can guarantee the long life of the protected installations.

Compressive strength: 650 MPa Min.

Density: 7-7.05 g/cm3

Hardness: 500 HB Min.

property: Requirement

-

Product name: High Silicon Tubular Anode

Material: silicon and iron

Technology: Casting

Certificate: ISO9001:2008

Standard: ASTM B843

Customization available

Delivery time: 20 days