PRODUCT DESCRIPTION

Best Quality Anti-corrosion Sacrificial Magnesium Anode Rod for Pipeline Oil Tank Cathodic Protection

made in China

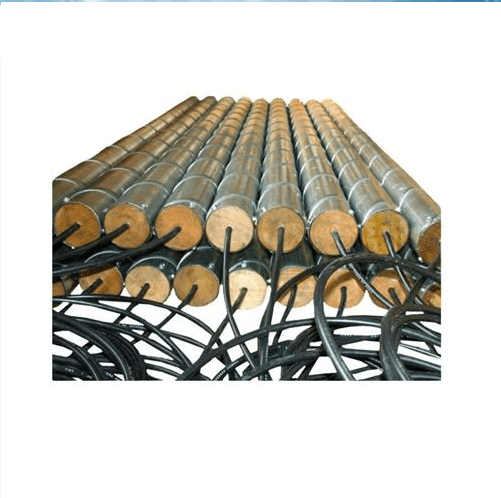

Howah Anti-corrosion magnesium anode rod used for Oil pipelines gas pipelines , water supply pipes and drain

-pipes.we also have a variety of shapes and sizes.our products have broad-specturm, such as: underground cables,

chemical plants, communications, harbors, water craft and reservoir strobe.

FEATURES

* Superconductivity

* Easy installation

* Low maintain cost

* Various size for choice

* Stable and Economy

CONSTRUCTION

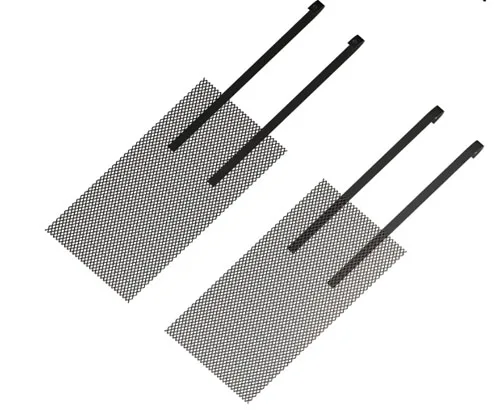

Packaged Anti-corrosion sacrificial Magnesium Anodes are prepack in either bags or cardboard carton in low

resistivity,quick wetting,prepared backfill.

PHYSICAL PROPERTIES

| Type |

Diameter

(mm) |

Weight |

High Potential L(mm) |

AZ63 anode L(mm) |

| C25 |

75 |

2.56 |

336 |

325 |

| C36 |

114 |

3.70 |

202 |

193 |

| C41 |

114 |

4.20 |

230 |

220 |

| C77 |

110 |

7.80 |

431 |

412 |

| C100 |

110 |

10.20 |

560 |

536 |

| C145 |

146 |

14.70 |

494 |

472 |

| C227 |

178 |

22.90 |

520 |

497 |

| C274 |

114 |

28.20 |

1528 |

1462 |

*Customized Size Available

STANDARD

ASTM B843-1995,GB/T21448-2008,GB/T17731-2009

QUALITY CONTROL

Quality Control in our foundry begins on the foundry floor, where the first line of inspection is the casting and molding

crew, our lab technicians inspectors and managers completes the quality team. Our quality control staff carefully

monitors raw material, core materials,packaging and all aspects of production.

APPLICATION