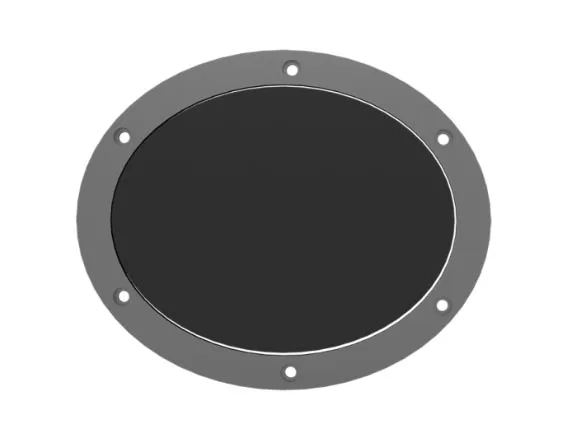

MMO Disc Hull Anode (Oval Shape)

This MMO disc anode is generally used in impressed current cathodic protection system for ship hulls. Surrounded by a dielectric shield to distribute the current evenly across the ships’ hull, it is suitable for use in fresh, brackish, and seawater environments.

The current emitting face of the disc anode is made from titanium substrate coated with a mixed metal oxide catalyst. When applied on titanium, the mixed metal oxide coating has an extremely low consumption rate, measured in terms of milligrams per year. Direct current transfer is accomplished through the mixed metal oxide catalyst which is highly conductive, so that higher current outputs are achievable. As a result, the dimensions of disc anodes remain nearly constant throughout the design life.

Shaped as a circular/elliptical flat plate, this slim disc anode fits flush with the hull surface, minimizing the drag resistance and maintaining the flow dynamics during voyages. Its low profile also avoids the problem of rubbing by anchor chains.