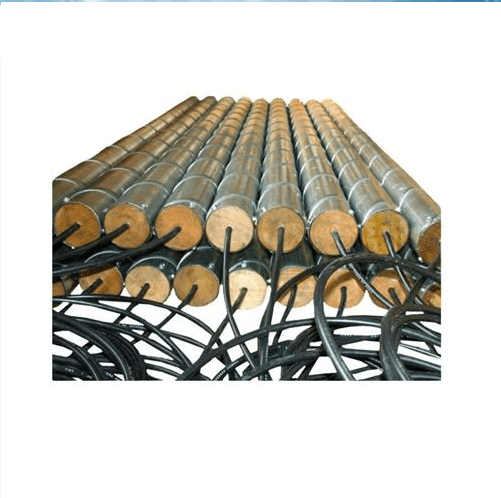

MMO Wire Anode

This MMO wire anode is manufactured using a high tensile solid titanium wire substrate (conforming to ASTM B348 Grade I/II) coated with a multi-layer noble metal oxide catalyst. The crystalline, electrically-conductive noble metal oxide coating activates the titanium wire and enables it to function efficiently as the anode. It is suitable for direct burial in fine sand, carbonaceous backfill and immersion in fresh or saline waters.

The MMO coated titanium wire anode has an extremely low consumption rate. The working life of the anode varies depending on the operating current present with the desired application. Longer life can be obtained by increasing the coating thickness or reducing the current density.

We manufacture MMO wire anode in three diameters: 1 mm, 1.5 mm and 3 mm. Our MMO/Ti wire anode can be connected to a feed cable at one end or ‘piggybacked’ to form a continuous anode suitable for installation under storage tanks or to provide continuous close protection for pipelines.

Furthermore, MMO wire anodes can also be used to protect the internal surfaces of water tanks where their malleable shape allows for even current distribution in areas where there can be large variations in water level.

Description

Noble Metal Oxide Coating

The noble metal film of the anode used depends on the operating environment. In soil or fresh water where there is either no chloride ions or low chloride ions present, therefore the Ir–Ta mixed metal oxide catalyst is recommended. For brackish and seawater, the Ir-Ru mixed metal oxide catalyst is recommended.

Low Coating Wear Rate

Stringent quality control procedures are followed throughout the coating process to ensure appropriate thickness and adhesion. Each batch is subject to thorough testing including accelerated life testing and coating thickness verification with X-ray among other tests.

Flexibility of Use

The lightweight and malleability of MMO wire anodes allow for adaptability in creating more complex configurations. They provide high conductivity, resulting in better current distribution along the entire length of the wire.

Main Technical Parameters

| Substrate | Titanium |

|---|---|

| Coating | Iridium Oxide (IrO2), Ruthenium Oxide (RuO2), Tantalum Oxide (Ta2O5) |

| Shape | Wire |

| Application | Pipelines, Storage Tank |

| environment | Brackish Water, Fresh Water, Horizontal Groundbed, Seawater, Shallow Vertical Groundbed, Soil |