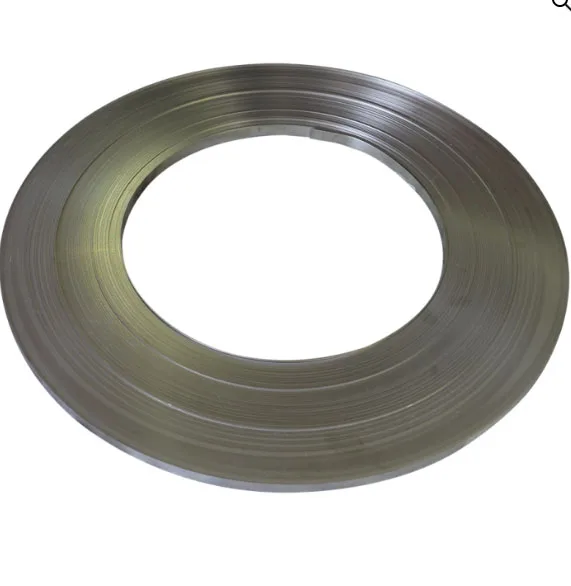

Titanium Conductor Bar

Regarded as an ideal auxiliary anode material, titanium conductor bars are a bus bar to interconnect anode elements. It is designed to evenly distribute current to MMO titanium-based anode for many cathodic protection(CP) and Electro-Osmotic-Pulse(EOP) applications.

Considering the attenuation of all linear anodes, sometimes auxiliary conductors must be augmented. The titanium conductor bar is particularly useful for controlling attenuation over long spans. It is commonly used with MMO ribbon anodes or MMO mesh anodes for impressed current cathodic protection of aboveground storage tank bottoms and reinforced concrete structures.

The titanium conductor bar and the MMO ribbon/mesh anode are laid vertically to form a lattice grid pattern, and the intersections are connected by spot welding. The connection to the power source is achieved by a special anode joint.

Description

Dimensional Stability

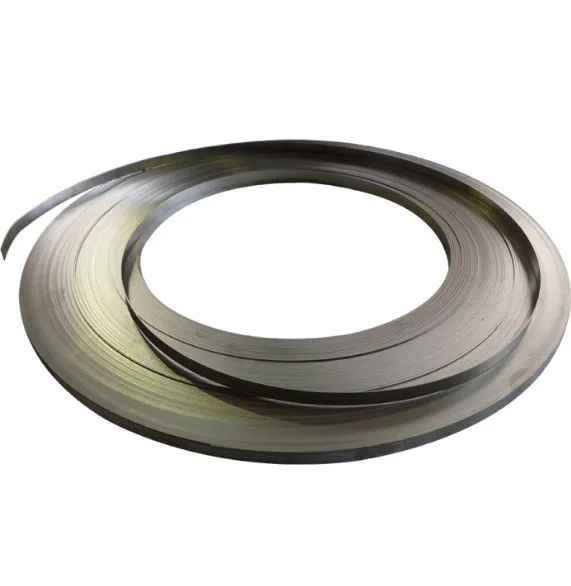

Thanks to its stable chemical composition, this aerospace material is mechanically strong as well as ductile. It is easy to form and install in applications where available space is restricted.

Excellent Corrosion Resistance

The titanium conductor bar is highly resistant to corrosion in various environments. It can be utilized in sandy soil, coke, seawater, brackish water and other complex environments with the presence of oxygen evolution, chlorine evolution or a mixture of the two.The titanium conductor bar is highly resistant to corrosion in various environments. It can be applied to sandy soil, coke, seawater, brackish water and other complex environment with oxygen evolution, chlorine evolution or a mixture of the two.

Easy Installation

Conveniently being cut and welded in the field, to suit various geometries, eliminating the need for time consuming saw cuts and grouting. This efficient installation helps reduce the total installed cost.

Long Working Life

The conductor bar is pure titanium and its chemical composition complies with ASTM B265 Grade 1. It can have a life expectancy of 50 years or more.

Dimensional Stability

Thanks to its stable chemical composition, this aerospace material is mechanically strong as well as ductile. It is easy to form and install in applications where available space is restricted.

Excellent Corrosion Resistance

The titanium conductor bar is highly resistant to corrosion in various environments. It can be utilized in sandy soil, coke, seawater, brackish water and other complex environments with the presence of oxygen evolution, chlorine evolution or a mixture of the two.The titanium conductor bar is highly resistant to corrosion in various environments. It can be applied to sandy soil, coke, seawater, brackish water and other complex environment with oxygen evolution, chlorine evolution or a mixture of the two.

Easy Installation

Conveniently being cut and welded in the field, to suit various geometries, eliminating the need for time consuming saw cuts and grouting. This efficient installation helps reduce the total installed cost.

Long Working Life

The conductor bar is pure titanium and its chemical composition complies with ASTM B265 Grade 1. It can have a life expectancy of 50 years or more.