Showing 65–80 of 89 results

-

Magnesium alloy sacrificial anodes are suitable for the anti-corrosion protection of such projects areoil pipelines, gas pipelines, water supply pipes, and drain-pipes, underground cables, chemical plants,communication, harbors, watercraft, and reservoir strobe.Standard:ASTM B843-1995,GB/T21448-2008,GB/T17731-2009

Magnesium alloy sacrificial anodes are suitable for the anti-corrosion protection of such projects areoil pipelines, gas pipelines, water supply pipes, and drain-pipes, underground cables, chemical plants,communication, harbors, watercraft, and reservoir strobe.Standard:ASTM B843-1995,GB/T21448-2008,GB/T17731-2009 -

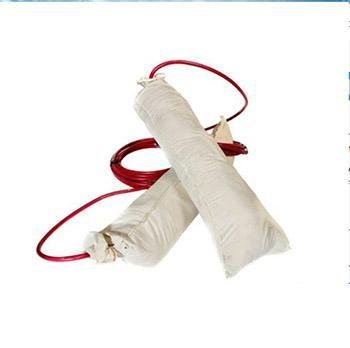

Prepacked Magnesium Anode

Product name: 32lbs Prepackaged Magnesium Anode

Chemical Composition: M1C (High Potential) AZ63B (Standard or Low Potential)

Bare Anode Specification:32Ibs/14.5kg 32D5 or customized

Backfill: Hydrated Gypsum, Hydrated Gypsum and Sodium Sulphate -

Rectangular Aluminum Hull Anode With Double Straps

The ship is continuously in contact with water and moisture-laden winds which makes it highly susceptible to corrosion. Corrosion is one of the greatest enemies of the ship main body and its machinery —— from the outer body (mainly hull) to the smallest equipment used in operations.

Characterized by lightweight and high amperage output, this rectangular aluminium hull anode will provide excellent protection for the hull on ocean-going vessels. The cast-in galvanized steel core allows for direct welding to the protected steel structure ensuring a reliable connection.

-

Rectangular Magnesium Hull Anode With Double Straps

Magnesium hull anode is commonly used for corrosion prevention on steel hull service boats in fresh water such as river boats, canal boats, cruising boats, etc. It is the best choice for fighting corrosion problems caused by stray current or pollution in freshwater. This magnesium hull anode with two cast-in galvanized steel straps can be either bolted or welded directly to a submerged structure.

-

Rectangular Magnesium Hull Anode With Single Strap

Magnesium hull anode is commonly used for corrosion prevention on steel hull service boats in fresh water such as river boats, canal boats, cruising boats, etc. It is the best choice for fighting corrosion problems caused by stray current or pollution in freshwater. This magnesium hull anode with cast-in galvanized steel straps can be either bolted or welded directly to a submerged structure.

-

Ruthenium Oxide Coated Titanium Electrode Plate

The chlorine evolution reaction (CER) has practical applications in the chlor-alkali industry and electrochemical wastewater treatment. Efficient, stable, and cost-effective electrodes are critical for energy efficient chlorine production, water disinfection, and wastewater treatment.

Ruthenium oxide coated anodes are regarded as the optimum choice in numerous industries due to its strong corrosion resistance, low overpotential for chlorine evolution, great physical stability and its environmental safety. Compared with traditional electrodes, ruthenium oxide coated electrodes have better electrochemical stability in sulfate/chloride environments and a longer service life.

Our electrodes have been utilized in industries such as the chlor-alkali industry, sodium hypochlorite production, seawater electrolysis, water treatment, electrowinning, etc.

-

Ruthenium Oxide Coated Titanium Electrode Plate

The chlorine evolution reaction (CER) has practical applications in the chlor-alkali industry and electrochemical wastewater treatment. Efficient, stable, and cost-effective electrodes are critical for energy efficient chlorine production, water disinfection, and wastewater treatment.

Ruthenium oxide coated anodes are regarded as the optimum choice in numerous industries due to its strong corrosion resistance, low overpotential for chlorine evolution, great physical stability and its environmental safety. Compared with traditional electrodes, ruthenium oxide coated electrodes have better electrochemical stability in sulfate/chloride environments and a longer service life.

Our electrodes have been utilized in industries such as the chlor-alkali industry, sodium hypochlorite production, seawater electrolysis, water treatment, electrowinning, etc.

-

Ruthenium-Iridium Coated Titanium Mesh Electrode

The chlorine evolution reaction (CER) has practical applications in the chlor-alkali industry and electrochemical wastewater treatment. Efficient, stable, and cost-effective electrodes are critical for energy efficient chlorine production, water disinfection, and wastewater treatment.

Ruthenium oxide coated anodes are regarded as the optimum choice in numerous industries due to its strong corrosion resistance, low overpotential for chlorine evolution, great physical stability and its environmental safety. Compared with traditional electrodes, ruthenium oxide coated electrodes have better electrochemical stability in sulfate/chloride environments and a longer service life.

Our electrodes have been utilized in industries such as the chlor-alkali industry, sodium hypochlorite production, seawater electrolysis, water treatment, electrowinning, etc.

-

Sacrificial Aluminum Hull Anode for boats

PRODUCT DESCRIPTION Anti-Corrosion System appliacation Sacrificial Aluminum Hull Anode for boats and basllast in any size with coating on the top Howah Sacrificial Aluminum Hull Anode Manufacturs all kinds of aluminum core configuration, so as to adapt to the different anode specifications and…

-

Sacrificial Extruded Magnesium mg metal Ribbon Anode for pipeline corrosion control system

PRODUCT DESCRIPTION New arrvial factory supply Sacrificial Extruded Magnesium Ribbon Anode 19×9.5mm for pipeline corrosion control system Howah Magnesium ribbon anode 9.5mm x 19mm for cathodic protection has a main application:the Cathodic protection of gas service entrance piping, it is also…

-

Sacrificial Magnesium Rod Anode for Water Heater&Tank

Extruded water heater boiler magnesium anode PRODUCT DESCRIPTION Wholesale Extruded Sacrificial Magnesium Rod Anode for Water Heater Boiler and Tank Cathodic Protection HOWAH Extruded water heater boiler magnesium anode are typically used for the Cathodic Protection of Water Heaters, Tanks and Boilers, and this water heater anodes are used for replacement applications. FEATURES * Softening…

-

Salt Chlorinator Cell

Productivity:20g/hour;30g/hour;50g/hour

Usage: Swimming pool water treatment

Core technology: MMO Coated Titanium Anode

Certificate: ISO9001

Warranty of core components:3 years

Delivery time: 20 days

Customized design available -

Segmented Aluminum Bracelet Anode (Tapered End, External Bolted)

This indium-activated aluminium bracelet anode is specifically designed for the cathodic protection of submarine/offshore pipelines. The segmented bracelet, consisting of multiple individual anode sections, is suitable for direct attachment around the circumference of a pipeline. The bracelet anodes shall be installed by means of a clamp. With tapered ends, our segmented aluminium bracelet anode is suitable for easy movements over stringer during pipeline laying.

-

Sheet Steel Test Station

Our test termination is composed of corrosion resistant nickel plated brass lugs to guarantee long term accurate reading, and all parts is easy to be removed with standard replacement.

-

Sodium Hypochlorite Electrolysis Generator

Substrate: GR1 Titanium

Shell: UPVC

Shape: tubular

Coating: Ru-Ir coating

Coating Thickness: about 10 microns

Demision: customized available Delivery time:20 days -

Straight Aluminium Hull Anode With Single Strap

The ship is continuously in contact with water and moisture-laden winds which makes it highly susceptible to corrosion. Corrosion is one of the greatest enemies of the ship main body and its machinery —— from the outer body (mainly hull) to the smallest equipment used in operations.

Characterized by lightweight and high amperage output, this straight shaped aluminium hull anode will provide excellent protection for the hull on oceangoing vessels. The cast-in galvanized steel core allows for direct welding to the protected steel structure ensuring a reliable connection.